The last years have been and are still being influenced by the COVID-19 virus, with various strains appearing currently and the tremendous worldwide effect on daily life and on the economy is still being felt. We sincerely hope that you and your families are healthy and that you are all doing well.

Hygiene and disinfection have always been a high priority but today are especially important. Subsequently the need for disinfectants and sanitisers such as chlorine dioxide ClO2, Peracetic Acid, Peroxide and others has increased dramatically.

Where Chlorine Dioxide is concerned, is one of the most effective disinfectants, capable of eliminating bacteria, viruses, molds, biofilms and even spores. It‘s function as biocide, algaecide, fungicide, makes it a very powerful general disinfectant while at the same time being very gentle with the items to be disinfected.

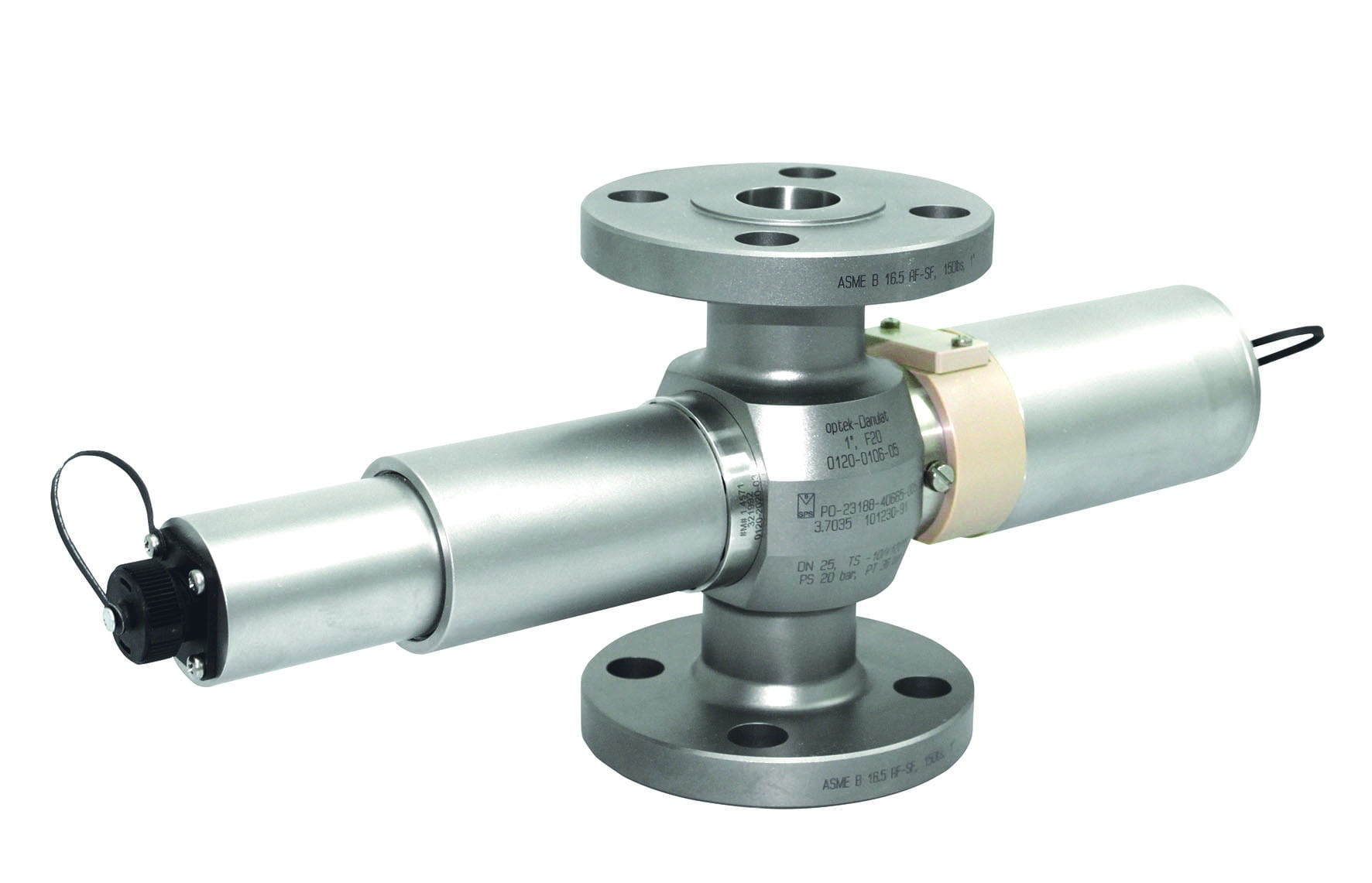

ClO2 is used in various applications, such as disinfection of drinking water, cleaning of medical instruments and personal protection equipment. In liquid solutions, we normally/typically measure ClO2 in mg/L or %. For workplace air applications the measurement is most commonly mg/m³. In all cases the ClO2 content must be controlled and accurately monitored. AMS and our partners have various options for monitoring liquids with Chlorine Dioxide and other disinfectors and sanitizers. Some of those analysers pass a small sample of the fluid passed a series of sensors, other are on line. For those applications where online monitoring is critical, this is where optek‘s sensors and converters come into play. Optek have been used in industrial applications for over 30 years.

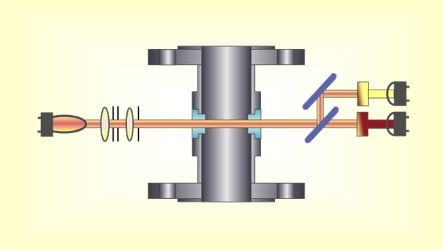

otek’s chlorine dioxide (ClO2) analyzers measure real time ClO2 solution strength and/or ClO2 gas concentration. For those unfamiliar with Optek photomers, the analyzer passes a light beam through the ClO2 stream to be monitored. The light absorbance is measured at two distinct wavelengths – one of which is measuring wavelength that corresponds to the ClO2 absorbance curve, while the second wavelength compensates for any other ‘influencer’ such as:

.

• window fouling

• particulate / suspended solids

• immiscible fluids

• gas bubbles

.

.

.

With the AF26 optical sensors and C4000 converters, optek is able to determine ClO2 levels in disinfectant solutions and residual levels remaining in the air of a room.

What do you do when you disinfect with ClO2?

Do you monitor online?

Or do you draw a sample through a series of sensors (pH & ClO2 typically)? (as shown)

Or do you ask a laboratory to check?

If it is important to know continuously then it is your chance to seize the opportunity and consider the possibility of monitoring and controlling ClO2 quantities directly and reliably, in real time. This might help you to comply with any legal regulations and ensure that employees are not over exposed to this disinfectant. Clearly there is a fine line to tread, but it is critical to know that sufficient ClO2 is used for disinfection to protect against COVID-19 and other viruses, molds, spores etc.

Stay safe!

Isn’t time to be more Analytical!

If you require any further information contact Peter Sims peter.s@ams-ic.com.au to assist you with any further information.