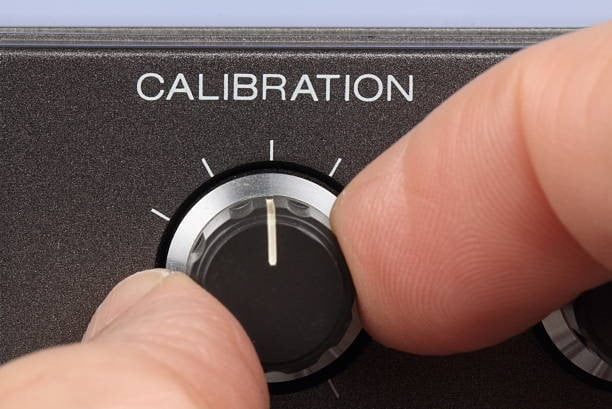

Calibration equipment stands as the silent hero behind accurate measurements, silently ensuring that the numbers we rely upon in various industries are precise and reliable.

From manufacturing plants to research laboratories, the importance of calibrated instruments cannot be overstated.

In this article, we delve into the world of calibration equipment, unveiling its critical role in maintaining measurement accuracy across diverse sectors.

What is Calibration Equipment?

At its core, calibration equipment refers to a collection of specialised tools that fine-tune and verify the accuracy of various measuring instruments.

The process involves comparing the measurement output of the instrument against a known standard to identify and correct any deviations.

This meticulous procedure not only guarantees the correctness of measurements but also upholds the credibility of the data generated.

The Importance of Calibration

Calibration is the cornerstone of measurement reliability. Through a systematic process, instruments are adjusted or corrected to ensure they consistently produce accurate and consistent results.

Calibration also bolsters the trustworthiness of measurement data, critical in fields such as environmental monitoring and industrial safety.

Industrial Applications Of Calibration Equipment

In the vast landscape of industries, periodic calibration equipment plays a central role in upholding quality standards and operational integrity.

Industries ranging from pharmaceuticals and petrochemicals to food and beverage manufacturing heavily rely on calibrated instruments for quality control, process optimization, and regulatory compliance.

Calibration finds its way into mining, energy production, and even water treatment, ensuring that measurements and data remain accurate, consistent, and dependable.

Types of Instrumentation and Calibration Services

- Electrical Calibration: These tools calibrate electrical equipment and ensure the accuracy of voltage, current, and resistance measurements, which are crucial in various fields like electronics manufacturing and energy distribution.

- Instrument Calibration: Covering a broad spectrum of instruments, this category includes tools that calibrate temperature, pressure, flow, and more. These ensure accurate data in sectors like HVAC, process control, and laboratory testing.

- Pressure Calibration: Pressure calibrators verify the accuracy of pressure measurements across a range of devices, from gauges to transmitters. Industries like oil, gas and manufacturing rely on precise pressure readings for safety and quality.

- Temperature Calibration: Used in sectors like pharmaceuticals, food processing, and research, temperature calibrators ensure that temperature-sensitive processes and products meet stringent standards.

- Flow Calibration: Indispensable in sectors like water treatment, food and beverage, and pharmaceuticals, flow calibrators verify the accuracy of flow measurement devices, ensuring the optimal functioning of critical processes.

- Mechanical Calibration: Mechanical calibration maintains the accuracy of mechanical instruments like torque wrenches, force gauges, and balances. These tools are vital in industries where precise force and weight measurements are essential.

Different Calibration Tools and Equipment

A comprehensive overview of common calibration tools unveils the essential instruments that ensure the integrity of measurement processes across industries.

Multimeters

These versatile devices are capable of measuring multiple electrical properties, including voltage, current, and resistance.

They play a pivotal role in electrical calibration, maintenance, and troubleshooting in industries ranging from electronics to power generation.

Pressure Calibrators

Vital in industries where pressure regulation is paramount, pressure calibrators accurately measure and adjust pressure levels.

They are indispensable for calibrating pressure transmitters, gauges, and regulators, ensuring optimal performance in sectors such as manufacturing and oil and gas.

Temperature Calibrators

Temperature calibrators are vital tools used to verify and adjust the accuracy of temperature measurement devices.

They simulate temperature conditions and compare the readings of the device under test with a reference standard.

This ensures the proper functioning of temperature sensors, thermocouples, and other temperature-sensitive equipment in various industries.

Calibration Benches and Workstations

Calibration benches and workstations provide controlled environments for calibrating various instruments.

These setups often include reference standards to ensure consistent and accurate results by minimising external influences, making them essential tools for maintaining measurement accuracy.

Calibration Software

The calibration software is a crucial tool in modern meter calibration processes. It enables precise and automated calibration routines, streamlining the calibration of various instruments.

With user-friendly interfaces, advanced algorithms, and data management capabilities, calibration software ensures consistent and accurate measurements while reducing human errors and enhancing efficiency.

Choosing the Right Calibration Equipment

Choosing suitable calibration equipment is a vital step in ensuring accurate and reliable measurements across various industries.

Here are key factors to consider when choosing the right meter calibration equipment:

- Instrument’s Intended Use: The nature of the instrument’s application guides the type of calibration equipment needed. Different industries have varying requirements, and selecting equipment that aligns with the instrument’s purpose ensures precise measurements.

- Required Accuracy: The level of accuracy needed for measurements impacts the choice of calibration equipment. High-precision instruments demand calibration tools that can deliver consistent and precise results.

- Compliance Standards: Many industries are bound by specific regulations and standards that dictate calibration procedures. Choosing equipment that meets these standards is essential to ensure compliance and reliability.

- Dependability: Opt for calibration equipment from reputable suppliers known for their quality and reliability. Inaccurate calibrations can lead to flawed measurements, product defects, and even safety hazards.

- Ease of Use: User-friendly calibration equipment simplifies the calibration process and reduces the risk of human error.

- Long-Term Support: Consider the availability of technical support, maintenance, and updates for the chosen calibration equipment.

Contact Us For Quality Calibration Equipment

From electrical to mechanical calibration equipment, we provide reliable solutions that ensure your instruments perform flawlessly.

Explore our comprehensive selection of calibration equipment and take the first step towards measurement confidence. Should you require tailored advice or solutions to meet your specific calibration needs, our trained professionals are just a click away. Trust us to be your partner in precision, efficiency, and accuracy.