We see a lot of leadership coming from Europe. Whether the science is right or wrong, the costs are real. So let’s take an Engineering rather than an emotional view of Combustion Analysers.

Made in Germany! A mark that has always carried a strong standing in the engineering community. That feeling remains true today. Many of us like that solid feel and sound engineering that come from companies that prefer quality over price.

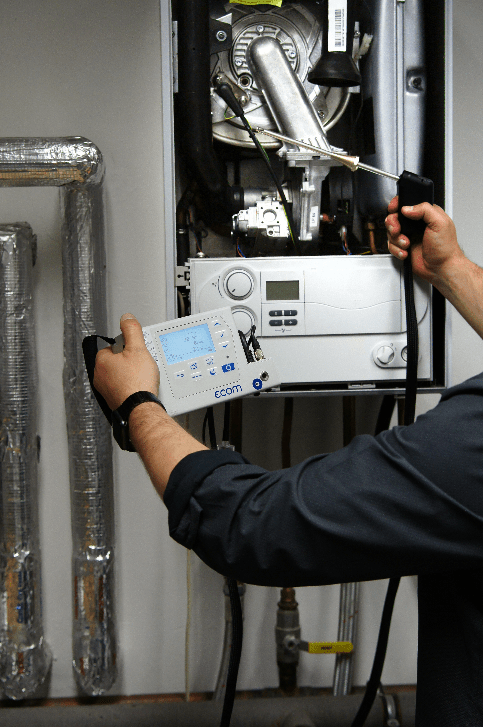

Ecom portable combustion analysers fit all of those German traits.

Combustion processes are everywhere, from the humble gas heater and hot water service to large industrial kilns, furnaces and boilers.

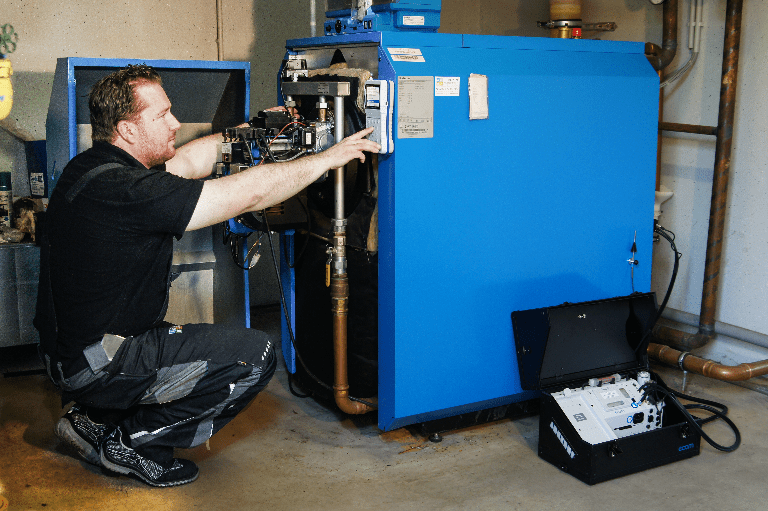

In some parts of the world it is essential that any combustion process is checked for efficiency and emissions performance annually or biannually. In parts of Europe Plumbers and chimney sweeps have a role to play in testing and approving household systems and larger Service Organizations or end users for Industrial applications. In Australia individual companies may choose to monitor their emissions to support their “Green Ambitions”, to be aware of cost implications of poor combustion, or to keep their eye on contractors who are paid to keep the combustion process optimal. In any of these instances rugged, well designed and simple to use equipment, like ecom, makes sense.

Those that choose to use 3rd Party organisations are, aware that choice rarely causes the responsibility to ‘pass’ on to those people of organizations. It is the process owner to be responsible so, while 3rd Party reports provide the arm’s length surety, day to day operations should continue to be prepared to monitor those processes. This is where ecom comes to your aid.

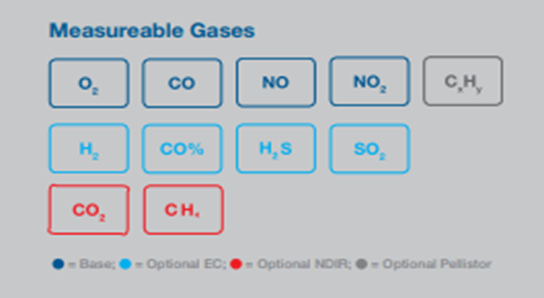

Ecom’s range is broad. Whether your need is to quickly monitor Oxygen and CO in a small boiler with a requirement for 5 minute sample runs for compliance or set up reasons. OR is a very sophisticated application that might need to monitor up to 9 gasses over 1 to 72 hours. There is a system for you.

As a company ecom has a slogan “We produce quality of life!“ It is ecom philosophy to link high-quality measurement technique with intelligent functions and services to the shortest measurement cycles, a structured, intuitive instrument operation as well as a comprehensive after-sales package. This has been their motivation for more than 30 years. Over that time ecom has been known for customer satisfaction and the highest technical measurement levels.

So, what else does the ‘Made in Germany’ tag get you?

Primarily it gets you better measurements over a longer service life. The key to compliance and your measurements. ecom electrochemical sensors are calibrated both on the gases and over a range of temperatures in an environmental chamber. To be precise, the reading accuracy of the gas sensors (CO, NO, SO2) is determined and adjusted at 5, 20 and 40°C in a climatic test chamber using standardised test gases.

Even the simplest portable analyser is compensated for the type of life they will see in the field! Added to that is a robustness not expected at all levels across the range. Hard on the outside – even harder on the inside! Almost all ecom measuring devices are housed in an ultra-light aluminium casing. Its durability pays off in its daily use – especially in rougher conditions.

The needs for a portable analyser can be broad. There are in my mind 4 separate styles of application, you might think of others, but let us explore my list:

HEATING

Combustion gas analysers, pressure meters, leak detectors and more for the HVAC heating, package boiler, furnace after-sales service. For control and adjustment works in order to reduce emissions and to optimize the efficiency of heating plants.

ENGINES

For control and adjustment works among all by commissioning of gas engines, thermal power blocks, etc. Here there are often water soluble gas like nitrogen oxide and others known as NOx or SO2 measurements.

COMBUSTION

Combustion gas analysers, pressure meters, leak detectors and more for control and adjustment works at burners and large-scale firing plants in order to reduce emissions, to arrange for a more efficient combustion process and to optimize the thermal process.

INDUSTRY

Combustion gas analysers, pressure meters, leak detectors. In Industrial applications there are likely more water-soluble gases (i.a. NO2 and SO2) and much more extreme conditions where the perfect preparation of the sample is critical. In industrial applications such as aluminium process, coke oven plants, cement processing, power plants, refineries, waste incineration…).

For applications where up to 6 gas measurement are expected the ecom-D finds a cost effective niche. It is extremely powerful and can, of course, include up to 6 gas measurements.

At the larger end. All ECOM analysers utilise electrochemical sensors to measure exhaust emissions, most commonly O2, CO. Some can additional use electrochemical sensors for NO, NO2, and SO2 gases. You might also consider NDIR bench for measuring CO2, high CO, and CH4 or Chemillumescence for NO/NOx. Transferring the sample from the exhaust pipe/duct utilizes a robust filtering system along with the Peltier gas cooler and 9V high-flow pump ensuring a clean sample and high flow rate, which is necessary for accuracy and repeatability.

An eye for detail ensures that the sensors are monitored closely and temperature changes are compensated for in even the harshest testing environments. For long life and better performance the CO sensor has a dedicated fresh air pump which is activated if a maximum concentration limit is exceeded, usually 4000ppm. The robust sample conditioning features, high-speed flow rate, and advanced sensor monitoring make the ecom-J2KNpro industrial analyser unmatched in performance.

These applications include emission testing on stationary engines, generators, compressors, boilers, burners, turbines, heating equipment, pumps, diesel engines, mining equipment (to control DPM), construction equipment, laboratory combustion equipment, alternative fuels research, and many other applications. The J2KN analyzer is also used for fuel efficiency testing, combustion tuning, maintenance checks, and emissions compliance reporting. The types of fuel burnt that can be tested on the J2KN series include natural gas, oil, diesel, coal, wood, biomass, butane, propane, biodiesel, and other alternative fuels. Fully loaded with sensor options and features, which allows it to be used in many different applications.. Gasoline emissions may be tested with the ecom-J2KNpro industrial, but this requires the NDIR bench (for CO).

AMS Instrumentation & Calibration Pty Ltd are the distributors of Ecom in Australia

- For further information you can also contact our Product manager – Peter Sims