Hawker Electronics offers ultrasonic level transmitters to a wide variety of industries.

Ultrasonic is the sound that is above the human hearing range. Humans can hear maximum up to a frequency of 20 KHz. Ultrasonic frequencies are above 20 KHz. Ultrasonic waves are used to measure the level of liquids and solid objects in industries. Ultrasonic level measurement is contactless principle and very suitable for level measurements for a wide range of liquids and bulk products like powders and grains and hot, corrosive and boiling liquids. The normal frequency range used for ultrasonic level measurements is within a range of 40 200 KHz.

What is the principle of ultrasonic level measurement?

Ultrasonic waves detect an object in the same way as Radar does it. Ultrasonic uses the sound waves, and Radar uses radio waves. When an ultrasonic pulse signal is targeted towards an object, it is reflected by the object and a sound wave returns to the sender. The time for a sound wave to travel back and forth to the process surface is used to calculate the distance and is interpreted by the transmitter electronics as process level. The ultrasonic level measurement principle is also used to find out fish positions in ocean, locate submarines below water level, also the position of a scuba diver in sea, etc.

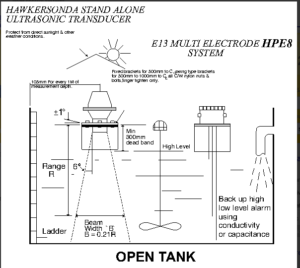

In above figure we intend to make an effort to understand the technicalities of an ultrasonic level transmitter. An ultrasonic level transmitter is fixed at the top of a tank half filled with liquid. The reference level for all measurements is the bottom of the tank (Range R). Level to be detected is anywhere in between the bottom of Range R and the high level mark. Ultrasonic pulse signals are transmitted from the transmitter, and are reflected back to the sensor. The travel time of the ultrasonic pulse from sensor to target and back is calculated. The measuring unit final result can be centimetres, feet, inches etc.

Advantages of Ultrasonic Level Transmitter:

Ultrasonic level transmitter has no moving parts, and it can measure level without making physical contact with the object. This typical characteristic of the ultrasonic level transmitter is suitable for measuring levels in tanks for a wide range of liquids and bulk products like powders and grains and corrosive, boiling and hazardous chemicals. The accuracy of the reading remains unaffected even after changes in the chemical composition or the dielectric constant of the materials in the process fluids. The ultrasonic level transmitters offer a reliable performance in difficult service applications

Limitations of Ultrasonic Level Transmitter:

Ultrasonic level transmitters are the best level measuring devices where the received sound wave of the ultrasound is of acceptable quality. It is not so convenient if the tank depth is high or the sound wave is absorbed or dispersed. The object should not be sound absorbing type. It is also unsuitable for tanks with too much smoke or high-density moisture.

AMS Instrumentation & Calibrations are distributors for Hawker Electronics. Hawker Electronics manufactures a complete range of level instrumentation apart from ultrasonics. This includes conductive, capacitance and pressure. Indication and control products to suit the level instrumentation also form part of the product range.

They are specialists in solving your application problems.

Hawker Electronics are a multi product manufacturing company as illustrated and explained within our Products pages. Hawker Electronics is an innovative company. Look at some of the new products we have developed.